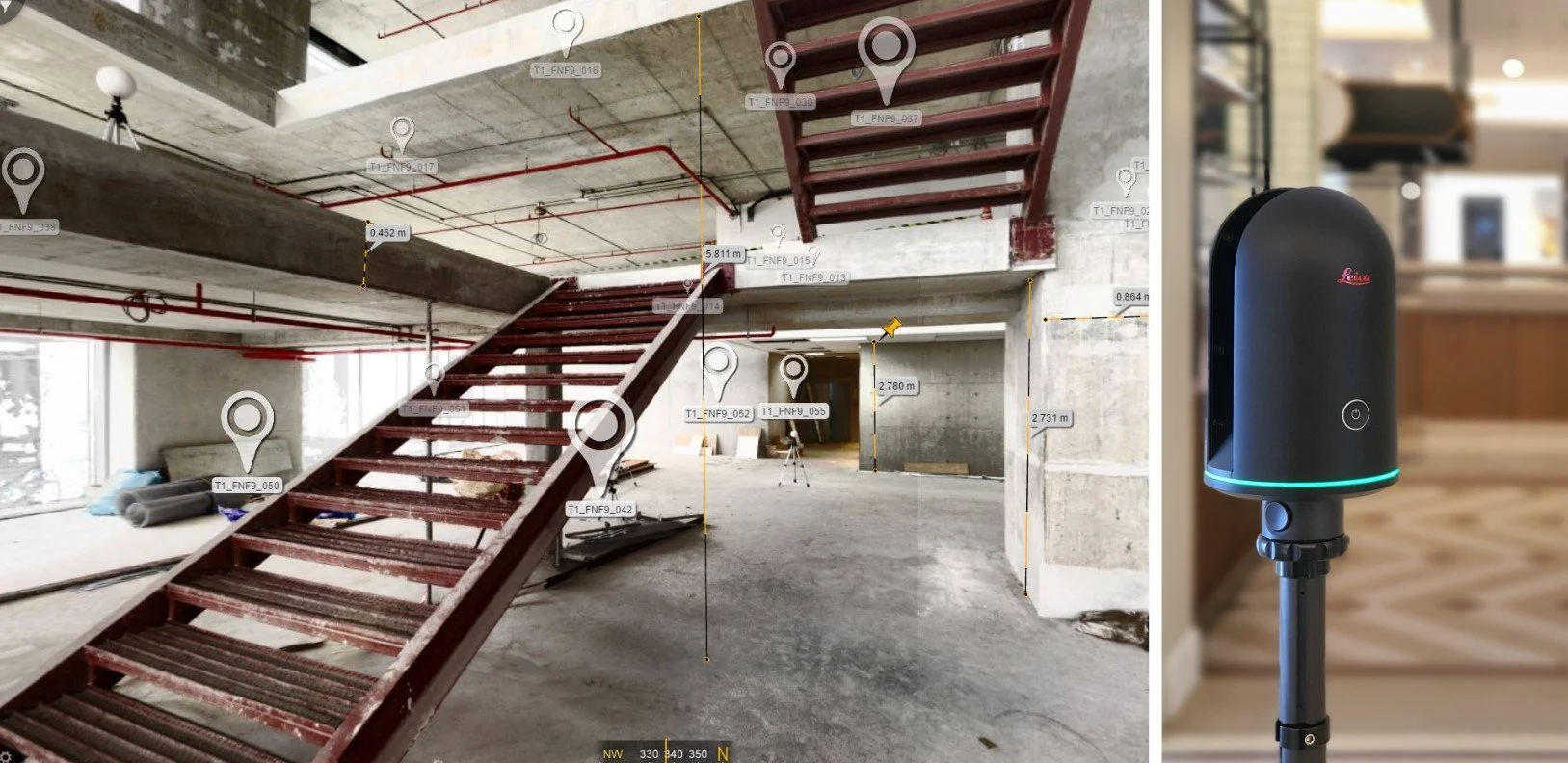

Experince 3D Scanning for Digital Site Setup & Parallel Construction

We founsd that Using 3D scanning to turn the jobsite into a high-accuracy digital model unlocks several powerful benefits. It completely changes how interior construction, built-ins, and paneling can be satrt in parallel, cut time and have a better quality control.

1. Accurate “Single Source of Data” for All Teams

3D scans capture the real as-built conditions with millimeter accuracy—including columns, beams, MEP, uneven floors, slopes, and deviations not shown in drawings.

Benefits:

Eliminates human measurement errors

Ensures all teams work from the same, most accurate model

Prevents costly rework due to mismatched dimensions

2. Faster Setting-Out and Layout on Site

Because the site is digitized, layout points for ceilings, walls, and floors can be extracted directly and accurately from the scan.

Benefits:

Faster marking and setting-out

Perfect alignment with actual conditions

Reduces clashes during installation

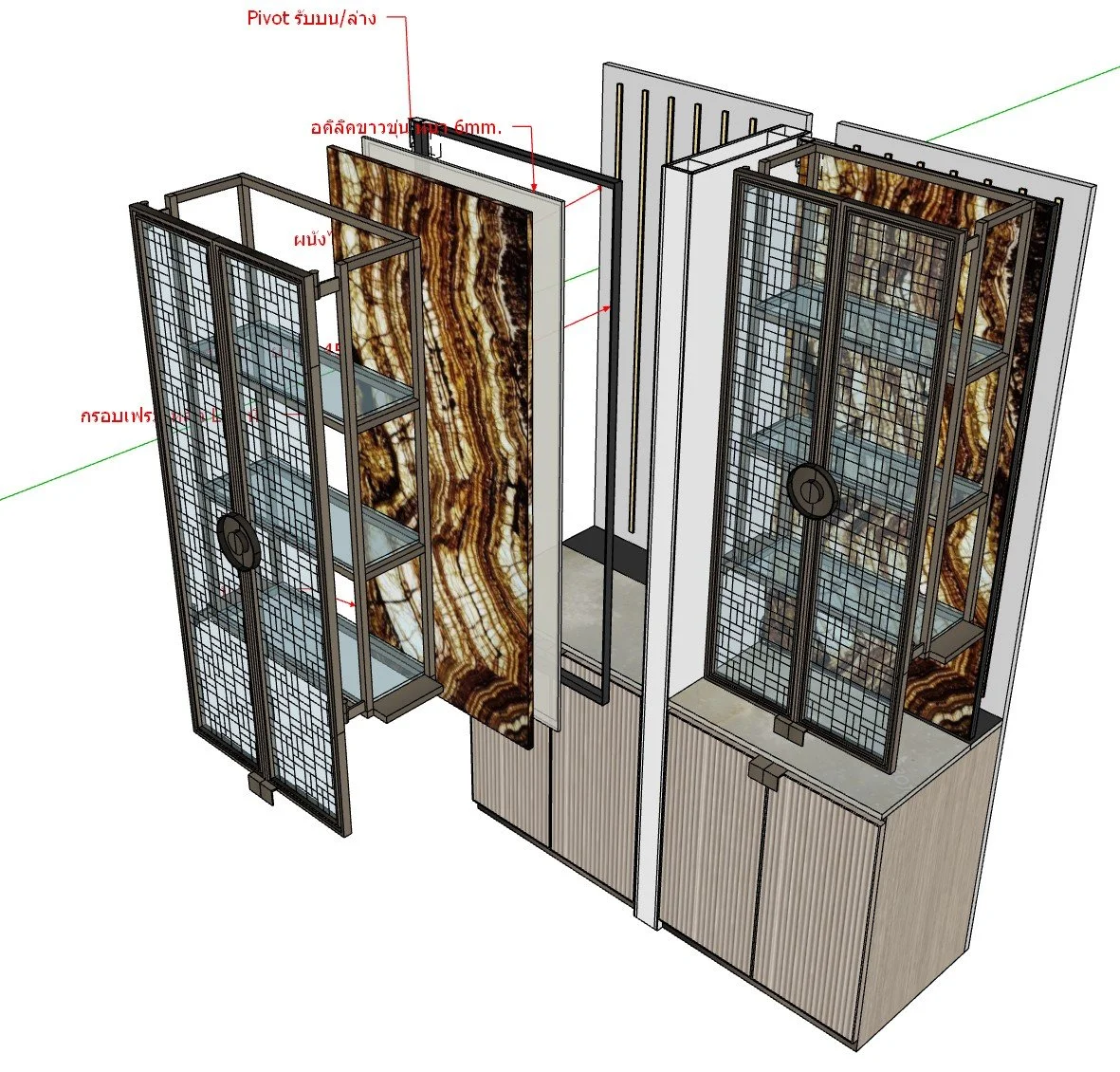

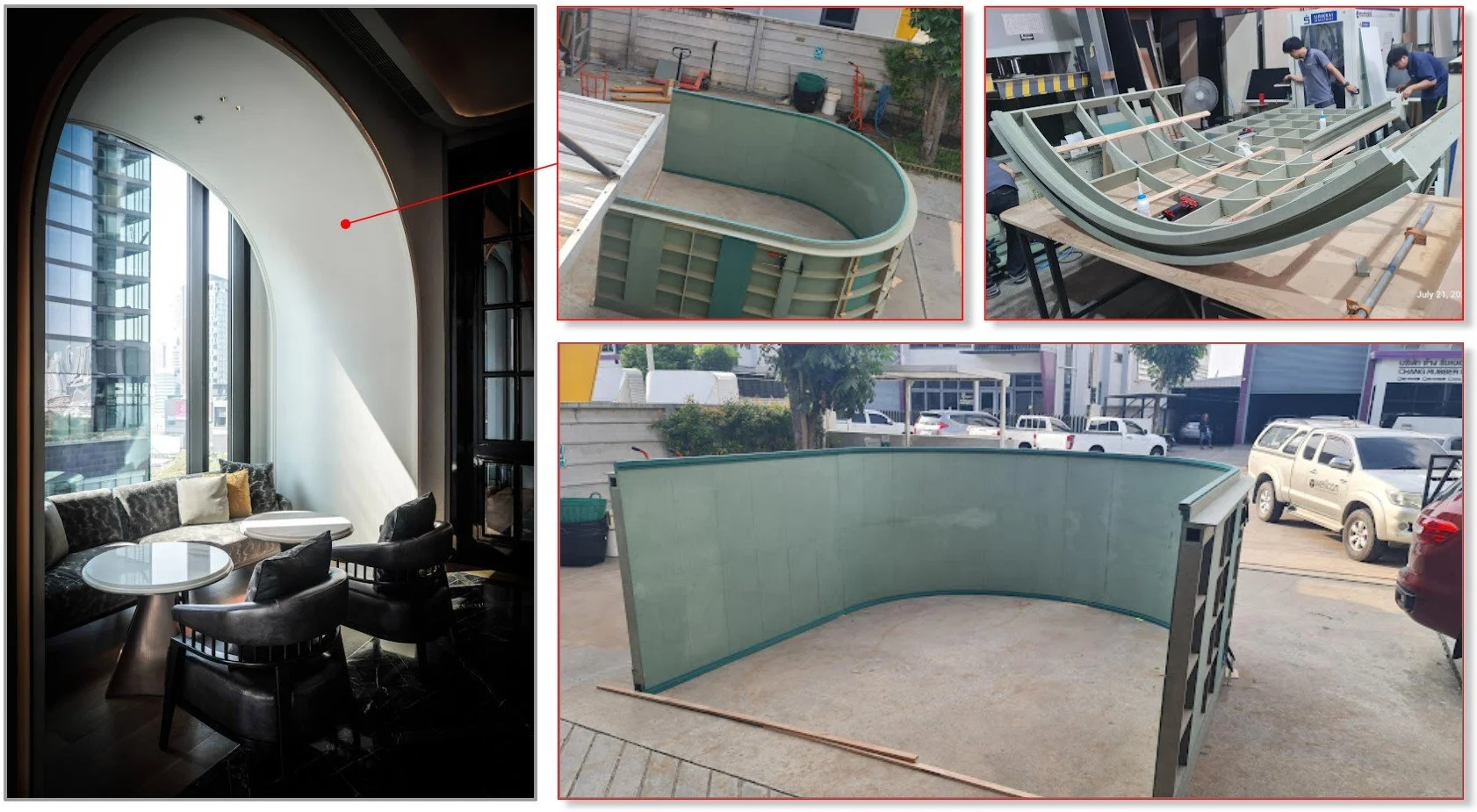

3. Enables Parallel Work: Site Work & Factory Work Can Happen Together

This is the biggest game-changer.

With accurate scan data, the factory no longer needs to wait for the site to be ready, because built-ins, wall paneling, and other prefabricated components can be fabricated based on the real as-built model, not theoretical drawings.

Benefits:

Ceiling, wall, and floor work can start immediately on-site

Factory can start producing built-ins and wall panels at the same time

Shortens total project duration by 20–40% (typical industry result)

Eliminates delays caused by “waiting for previous trade to finish”

4. Perfect Fit for Built-ins and Paneling (Minimize On-site Modification)

Factories can fabricate components to exact dimensions, including:

Out-of-square rooms

Sloping floors

MEP penetrations

Actual beam depths

Benefits:

Installations become “plug-and-play”

Reduces site cutting, patching, or adjustments

Higher quality finish

Less noise, dust, and disruption

5. Early Clash Detection Before Installation

The digital model helps detect:

MEP conflicts with built-ins

Ceiling height issues

Paneling alignment problems

Door/window and structure conflicts

Benefits:

Solves problems in the computer, not on-site

Prevents rework and saves cost

6. Transparent Communication with Owners & Consultants

A 3D scanned model is easy for clients to understand. It helps explain:

Actual site conditions

Necessary adjustments

Progress checks

Benefits:

Builds trust

Reduces disputes

Speeds up approvals